Fridge, Water Heater, and Solar Panels

Yesterday, we went shopping for appliances. Found some we liked, all with good Energy Star ratings, so we thought they would be fine. Today, I looked at the energy use of the fridge, and now everything is in question, as we re-evaluate water heater and solar panels.

Let me back up a bit.

Solar panels

Solar panels are great, and we had planned to add them. However, the electricity in Kanab is too cheap, and the cost of solar is still dropping, so when we ran the numbers, it makes more sense to add those in a few years.

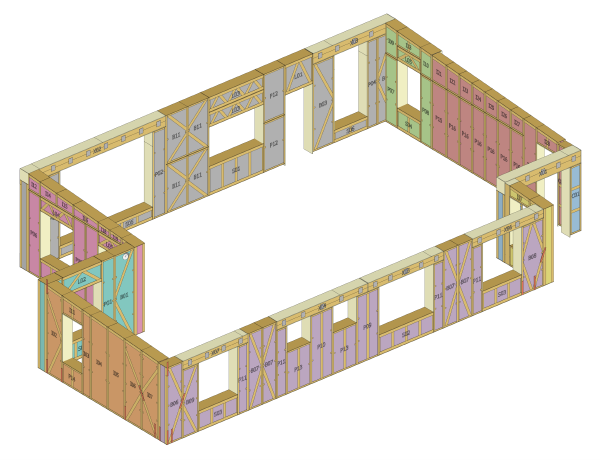

Walls in Container

Our house is making progress: the architectural committee of the HOA has accepted the design, Kanab has granted us a building permit, and the walls are in the container.

You read that right. We’re using load-bearing straw panels by EcoCocon: the compressed straw and load-bearing wood frames provide excellent insulation with no thermal bridges. The 100 panels are custom made for our house:

Passive House Certification

I had planned to have the house certified by both PHI and PHIUS. For PHI, we’ve already done a lot of the work using the PHPP spreadsheet, and for PHIUS, we could use the simplified prescriptive path for certification. A lot of the necessary documentation, blower door test, etc., would be shared, and the PHIUS certification would help us qualify for some tax rebates.

However, while our house is simple enough for the PHIUS prescriptive path, it has too many windows. Especially after the smaller redesign, the window-to-wall and especially the window-to-floor-area ratios were not within the limits for the prescriptive path. (Corrected May 6: Adequate Exposure Diversity would pass as an alternate to the window-to-floor-area.) We would have to use the performance path for certification, and that would involve hiring somebody to calculate the WUFI model for the house. It would have been great to compare the PHI and PHIUS results, but we’ve decided that the extra cost is not worth it. So we’re proceeding with PHI certification only.

Clay Delay

Remember back when I discussed the lot and mentioned that clay soil was a common problem in Kanab? We were glad to know that our lot had already been over-excavated and prepared such that we didn’t have to worry about clay.

Well, while digging the trenches for the stem walls, they found clay in one corner.

Not good. Clearly, something went wrong while preparing the lot, and the company who did that work will be back to fix their mistake. All on their dime, so at least we’re only out time, not money. But it means a delay of about two weeks, so the walls will arrive before the foundation is ready, and thus need to be stored for a bit, complicating the logistics.

Insulated Foundation

All houses need a strong foundation, but that’s not enough for a passive house. The whole envelope of the house needs to be insulated, and the foundation needs to do its part in keeping the heat in (or out).

Here’s a basic diagram of a slab foundation, with footings under the outside walls as well as the interior load-bearing walls. Without any insulation, heat will escape through the concrete slab.

Solid Ground

Finally – our lot now has something other than dirt and a porta-potty: the concrete footings around the house have been poured!

It took some steps to get there. After the clay had been removed, that big hole had to be filled with good dirt, compacting it along the way. And some of the trenches had to be dug again.

Concrete Progress

Insulation Matters

The insulated foundation looks clean and simple on paper: 4 inches of insulation everywhere around the slab, making sure there’s no way for heat to escape from the concrete slab to either ground or stem wall without going through at least 4 inches of insulation. (That amount of insulation provides an R-value of about 20; 4 inches of concrete has an R-value of less than 1.)

When I arrived to check on the work in progress, the reality was not quite as simple, and would definitely not insulate as required. The stem wall is where the temperature differences are biggest, so that’s where the insulation matters most.

Pouring the Slab

The slab was poured on Monday July 15, starting at 7 am. The whole operation went very smoothly. They were careful to push the insulation into place as the concrete was poured, to avoid the concrete flowing into cracks.

Moving the house a few feet westward paid off: the ready mix truck could get through on the east side and deliver concrete from the back, eliminating the extra cost of pumping the concrete.

Base Plate

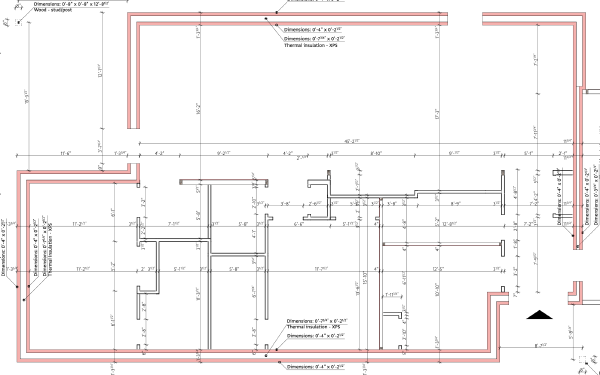

The wall panels need a base plate to stand on. The base plate goes around the perimeter of the house – the red ring in the following image:

The base plate fulfills several functions:

- It moves the straw panels a few inches off the ground to protect them from any future water mishap.

- It’s firmly tied down to the concrete, and in turn gives a solid base to screw the panels into.

- It’s the first step in creating an airtight layer around the whole house.

In essence, the base plate consists of two support beams with insulation in-between. Underneath, a waterproof layer separates the wood from the concrete. Here’s an image of the base plate under construction: