Insulation Matters

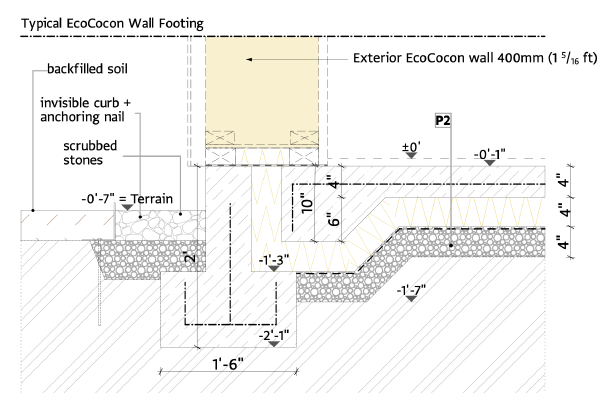

The insulated foundation looks clean and simple on paper: 4 inches of insulation everywhere around the slab, making sure there’s no way for heat to escape from the concrete slab to either ground or stem wall without going through at least 4 inches of insulation. (That amount of insulation provides an R-value of about 20; 4 inches of concrete has an R-value of less than 1.)

When I arrived to check on the work in progress, the reality was not quite as simple, and would definitely not insulate as required. The stem wall is where the temperature differences are biggest, so that’s where the insulation matters most.

The stem wall was supposed to be 15 inches tall on the inside, but only the top 12 inches were straight, the bottom 3 inches were rough due to the concrete flowing out below the form. This made it hard to put the insulation up against the stem wall. Using a double layer of 2-inch insulation also made everything harder than it needed to be.

The drawings show a ramp from the slab down to the thickened edge of the slab; the concrete guys wanted to keep it simple and decided to use a boxy solution. That makes the thermal boundary larger than with the diagonal, in essence increasing the slab surface a bit. It will work, but the way they had started doing it was not going to guarantee enough insulation in all directions.

Adding more insulation along the inside of the thickened edge of the slab improved the insulation, but reduced the width of the thickened edge to 6 inches in some places; the engineering plans called for 8 inches minimum.

So the project slipped again while we fixed up the insulation as best we could. In places where we couldn’t double up the insulation due to the thickened edge getting too narrow, we added insulation behind. It’s not perfect; the way it was done there’s no guarantee that it will be R-20 everywhere, but I think we managed to avoid any thermal bridges. After adding a bunch more insulation and foam, it looked much improved.

Interior footings

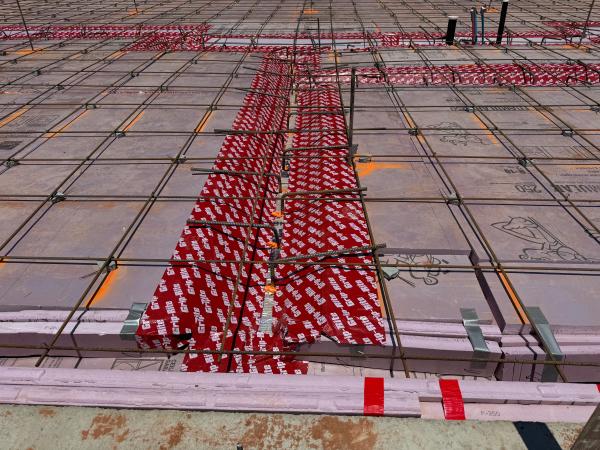

The plans called for foam glass on top of the interior footings (below the interior load-bearing walls), but the supplier instead provided polyiso. Our passive house certifier has opinions: it will work, but not quite as well.

Adding a bunch of tape helps keep moisture away from the polyiso, and keeps concrete from going down into any cracks and pushing up the insulation.

Ready for concrete

Here are some more pictures from shortly before pouring the slab.

Note the thinner insulation and wall against the garage; the EcoCocon panels there are ‘only’ 30 cm thick instead of 40 cm.