Windows

Windows are a balancing act between light, views, insulation, heat gain, and of course cost. Passive house windows need to be triple-pane, their frames need to insulate well, and they need to seal tightly, so they will necessarily cost more than regular windows.

Detailed quotes

We got quotes from multiple vendors, and made a lot of changes in response to those quotes, optimizing number, size, and type of windows. To do that, we needed detailed quotes listing the cost for each window, instead of just giving us one (very large) number. Without that, you’re limited in knowing what you can do to keep costs down.

We had great experiences working with the following window vendors, each of which gave us detailed quotes:

- Alpen: thinkalpen.com (in Colorado)

- SmartWin / Advantage Architectural Woodwork: advantagewoodwork.com (in Kansas)

- Neuffer: neuffer-windows.com (in Germany)

While these are all excellent windows, the SmartWin windows have the best performance, and are also a bit more expensive. Unfortunately, their lead time was too long, so we decided to go with the Tyrol series of windows by Alpen, and a wooden front entry door by Neuffer.

Optimizing windows

The easiest way to reduce costs is to remove a window. We had planned to have a window in the garage, but removing that one was an easy way to save $1,000.

Fixed windows are significantly cheaper than operable panes.

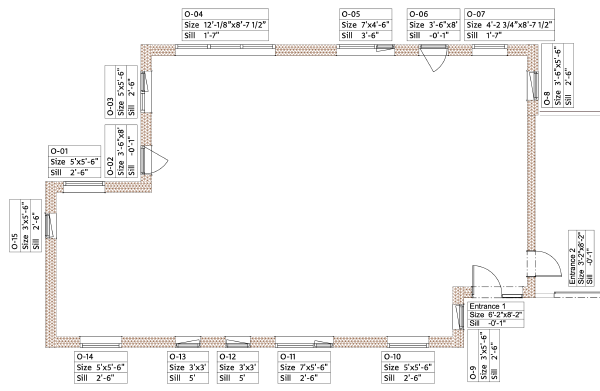

- We had a kitchen window with two operable panes (O-05 below); reducing it to one operable pane (while keeping the overall size the same) saved $800.

- In the office, we had one fixed window (O-09), and one part fixed / part operable window (O-10). Changing the fixed window to be operable and making the larger window fixed saved about $400. Removing the mullion from the south-facing window also improved its thermal performance.

The ventilation in a passive house brings in fresh air all the time, so you don’t need a lot of operable panes just for fresh air. But you do need at least one operable pane in each room for egress in case of fire.

Size limits

You’ll want to figure out the maximum window size, not just for manufacturing, but also for transport. There may be a maximum height for getting a window in a truck, which may be a lot cheaper than having to transport it in a different way. We reduced the height of O-04 by 5 inches to make it fit into the truck, and we reduced the width of O-07 due to limits on the glass size.

Pressure balloons

Kanab is at an altitude of 5,000 ft. Good window panes are filled with argon gas at the factory. With the reduced air pressure in Kanab, the windows would bulge outwards, which is undesirable, to say the least.

To deal with that, some manufacturers add valves in the windows to equalize the pressure. Of course, as you go over mountain passes to get to Kanab, you’ll lose some of that argon, and the windows will be less efficient.

Both Alpen and SmartWin deal with this issue the right way. They attach tubes with pressure-equalizing balloons to each window, so that the argon can move in and out as the altitude changes during transport. Once the windows get to their destination, those tubes are sealed and the balloons are removed.

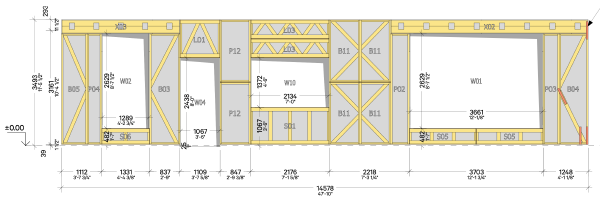

Wall openings

In a traditional build, you have some ability to adjust the window openings on the fly. As we’re using EcoCocon panels manufactured specifically for this house, we have to make sure the wall openings and the windows match. The windows are 3/4 inch smaller than the openings – only 3/8 inch margin on each side.

We’ve checked, we’ve double-checked, we’ve triple-checked – we hope we got it all exactly right.